Molding process ndiyo imwe chiyero che prepreg mukati mesimbi mold mhango ye mold, kushandiswa kwezvitsigiro zvine sosi yekupisa kuburitsa imwe tembiricha uye kudzvanywa kuitira kuti prepreg iri mugomba remuvhu inyoroveswe nekupisa, kuyerera kwemhepo, kuzere nekuyerera, kuzere ne mold cavity kuumba uye kurapa zvigadzirwa zvemaitiro nzira.

Molding process inoratidzwa nekudikanwa kwekudziya mukuumbwa, chinangwa chekudziya ndechekuita prepreg mukunyorovesa kwekuyerera kwe.resin, kuzadza iyo mold mhango uye nekumhanyisa maitiro ekurapa eiyo resin matrix zvinhu. Munguva yekuzadza iyo mold cavity ne prepreg, kwete chete resin matrix inoyerera, asiwo inosimbisa zvinhu, uye resin matrix uye inosimbisa fiber inozadza zvikamu zvese zvegomba panguva imwe chete.

Chete cheteresinmatrix viscosity yakakura kwazvo, chisungo chacho chakasimba kwazvo, kuitira kuti chiyerere nesimbi inosimbisa, saka nzira yekuumba inoda kuumbwa kwakakura, kunoda kuumbwa kwesimbi kune simba rakakwirira, kusimba kwepamusoro uye kusagadzikana kwekuora, uye inoda kushandiswa kwemashizha anopisa anopisa kudzora tembiricha yekurapa kuumbwa, kumanikidza, kubata nguva uye mamwe maitiro ekugadzirisa.

Kuumba nzira yekunyatso kugadzirwa, kurongeka kwehukuru hwechigadzirwa, kupedzisa kwepamusoro, kunyanya kune yakaomesesa dhizaini yezvakasanganiswa zvigadzirwa zvinogona kuumbwa kamwe chete, hazvizokanganisa kuita kwezvakasanganiswa zvigadzirwa. Kukanganisa kwayo kukuru ndeyekuti kugadzirwa kwe mold uye kugadzira kwakanyanya kuoma, iyo yekutanga mari yekudyara yakakura. Kunyangwe iyo nzira yekuumba ine zvikanganiso zviri pamusoro, iyo mold process ichiri nenzvimbo yakakosha mucomposite material yekuumba maitiro.

1, Gadziriro

Ita basa rakanaka reprepreg, kuumba zvigadziriso zvekugadzira, nechoto chekuedza chidimbu chebasa rinotsigira, uye kuchenesa mold mukushandiswa kwekupedzisira kwemarara, tsvina, kuchengetedza mold yakachena uye yakatsetseka.

2, Kucheka uye kuisa prepregs

Ichagadzirwa kuita chigadzirwa checarbon fiber raw materials yakagadzirira, prepreg mushure mekupfuura ongororo, kuverenga nzvimbo yezvakagadzirwa, zvigadzirwa, huwandu hwemashiti, iyo yakaomeswa dhizaini nerusenzi yakawedzerwa kumusoro, panguva imwe chete pamusoro peiyo superposition yezvinhu zve pre-kudzvanywa, yakatsikirirwa muchimiro chenguva dzose, kunaka kweimwe nhamba yezvikamu zvakakora.

3. Kuumba uye kurapa

Isai akaturikidzana mbishi zvinhu muforoma, uye panguva imwe chete mukati mukati epurasitiki airbags, vhara mold, yose kupinda molding muchina, mukati epurasitiki airbags pamwe imwe anogara kudzvinyirirwa, nguva dzose tembiricha, kuisa nguva dzose, kuti kurapa kwayo.

4, Kutonhorera uye kudhiza

Mushure menguva yenguva yekumanikidza kunze kweforoma kutanga kutonhora kuziva kwenguva yakati, uye wozovhura mold, demolding kunze kweziso kuti uchenese tooling mold.

5, Kugadzira kuumba

Mushure mekudzikisa chigadzirwa chinoda kucheneswa, nebhurashi resimbi kana bhurashi remhangura kukwenya kubva papurasitiki yasara, uye kufefeta nemhepo yakamanikidzwa, chigadzirwa chakaumbwa chinokwenenzverwa, kuitira kuti nzvimbo yacho iite mutserendende uye yakachena.

6, Nondestructive kuyedzwa uye kuongorora kwekupedzisira

Kuedza kusingaparadzi uye kuongorora kwekupedzisira kwezvigadzirwa kunoitwa maererano nezvinodiwa zvemagwaro ekugadzira.

Kuongororwa kwehunyanzvi mapoinzi e prepreg molding process

Kubva pakuzvarwa kwekabhoni fiber composites, yakagara ichiganhurwa nemutengo wekugadzira uye kukanganisa kwebhiti dzekugadzira, uye haina kushandiswa muhuwandu hukuru. Sarudza mutengo wekugadzira kabhoni fiber uye kurova ndiyo nzira yekuumba,carbon fiber composite zvinhukuumba maitiro kune akawanda, akadai seRTM, VARI, hot press tanks, oven curing prepreg (OOA), nezvimwewo, asi kune mabhodhoro maviri: 1, nguva yekuumba nguva yakareba; 2, mutengo unodhura (uchienzaniswa nesimbi nemapurasitiki). Prepreg CompressionMolding, semhando yekuumba maitiro, inogona kuona kugadzirwa kwebatch uye kuderedza mutengo wekugadzira, uyo unowedzera uye unoshandiswa zvakanyanya.

Prepreg molding process inoreva tembiricha, kudzvanywa, mune imwe nguva yenguva ichave prepreg yakapararira mune pre-yakaumbwa muviri compression molding. Kumhanya kwekuumbwa kweichi chiitiko kunokurumidza, zvinodiwa zvemidziyo zviri nyore, zviri nyore kushandisa, zvichienzaniswa neanopisa tangi yekudhinda, VARI uye OOA maitiro, chigadzirwa chakanakisa mune ese ari maviri epamusoro emhando yemhando, yakanaka dimensional kugadzikana, maitiro ari nyore kudzora.

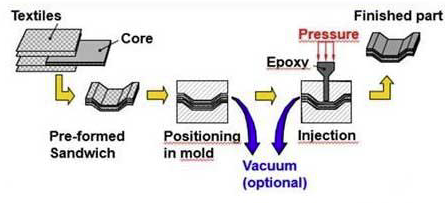

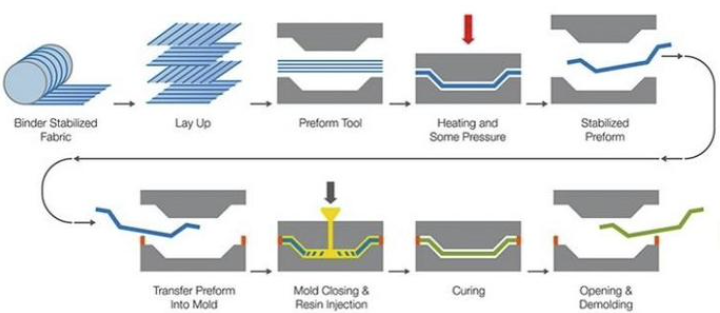

▲ Pre-preg molding process flow chart

Zvinhu zvina zvekugadzira nzira

1. Tembiricha uye kufanana: kuratidza mwero wekuita pakatiresinuyekurapa mumiriririuye kufanana kwenzvimbo yekuita, kunyanya kudzora kunaka kwekuumbwa kwepamusoro uye dhigirii rekurapa;

2. Kudzvinyirira uye kufanana: kuratidza kubuda kwemhepo uye kuyerera kwemhepo mu resin, kutonga kuumbwa kwepamusoro uye maitiro emagetsi;

3. Kureba kwenguva yekurapa: kuratidza dhigirii rekurapa, kuve nechokwadi chekugadzirwa kwekugadzira;

4. Mold cavity makubvu: kuratidza ukobvu hwechigadzirwa, zvinoenderana neakakosha maitiro eiyo carbon fiber material pachayo, gadzira inonzwisisika gobvu gobvu.

Process kushanda

Prepregkuumba maitiro kunogona kugadzira chero chimiro chechigadzirwa, chimiro chechigadzirwa kana chakanyanya kuomarara, senge inverted buckle, yakawandisa flange nzvimbo, zvichikonzera kuwedzera kwakanyanya mumutengo wekuumbwa uye kuomerwa kwekugadzira, saka kune chimiro chezvakanyanya kuoma zvimedu zvekushandisa hazvina kusimba, asi isu tinogona kuve optimization yemaitiro kana block dhizaini + bonding mhinduro kugadzira zvikamu zvakaoma.

Inoenderana Technology

1. Multi-layer Cutting Technology: Multi-layer prepregs inochekwa panguva imwe chete; prepregs nemakona akasiyana anochekwa panguva imwe kuti avandudze kucheka kunyatsoita.

2. Tekinoroji inopisa-in / inopisa-kunze: iyo mold inopisa zvakananga kuhutano hwekuporesa, uye preform inoiswa muhutu uye inomanikidzwa kuita chimiro, iyo inopfupisa nguva yekuumba uye inoderedza kushandiswa kwesimba.

3. Net-saizi molding tekinoroji: iyo preform inoroverwa kune net-saizi kutanga, uye wozoisa mu-net-saizi mold yekurapa, kuderedza nzira yekucheka.

Maitiro Matambudziko

Kuomerwa mukugadzira molds yezvakaoma zvigadziriso zvigadzirwa: Kana paine akawanda inverted mabhegi uye asina kunaka makona mune zvigadzirwa, izvo zvinoita kuti mold dzinyanye kuomesesa kugadzira, uye panguva imwecheteyo, mushure mekushandiswa kwekuumbwa kwenguva yakareba, zvinotungamira mukudzikira kweiyo chaiyo yekurongeka kweiyo inoiswa. Naizvozvo, paunenge uchigadzira chigadzirwa, edza kudzivirira iyo inverted buckle kana yakaipa angle.

Cherechedza: zvikamu zvekunze zvekuvhara zvechigadzirwa chepamusoro zvinodiwa zvakanyanya, carbon fiber zvinhu zvikamu zvezvinetso zvakajairika ndezvi: chigadzirwa dova texture zvikamu machena mavara; chigadzirwa chakakanganisika magadzirirwo matambudziko; pamusoro pepinholes, kushaikwa kwezvinetso neglue, zvichingodaro. Kupfupisa zvikonzero, mumiririri wekurapa mune prepreg haina kufanana yakasanganiswa kana kuita hakuna kukwana; kutonhora kwe mold hakusi yunifomu; tembiricha uye kumanikidza hazvisi munzvimbo; iyo mold dhizaini uye kugadzirisa haisi panzvimbo; iyo nzira yekuumba haina kudzorwa; mouldkusunungura mumiriririanopindura, zvichingodaro.

Nguva yekutumira: Jan-17-2025