Inqubo yokubumba iyinani elithile le-prepreg emgodini wesikhunta sensimbi wesikhunta, ukusetshenziswa komshini wokunyathelisa ngomthombo wokushisa ukukhiqiza izinga lokushisa elithile nokucindezela ukuze i-prepreg emgodini wesikhunta ithambe ngokushisa, ukugeleza kwengcindezi, okugcwele ukugeleza, okugcwele ukubunjwa kwe-mold cavity kanye nemikhiqizo yokwelapha yendlela yenqubo.

Inqubo yokubumba ibonakala ngesidingo sokushisa enqubweni yokubumba, inhloso yokushisa ukwenza i-prepreg ekuthambiseni kokugelezainhlaka, ukugcwalisa umgodi wesikhunta futhi usheshise ukusabela okuphulukisayo kwempahla ye-resin matrix. Ngesikhathi senqubo yokugcwalisa umgodi wokubumba nge-prepreg, hhayi kuphela i-resin matrix egelezayo, kodwa futhi nezinto eziqinisayo, futhi i-resin matrix kanye nemicu yokuqinisa igcwalisa zonke izingxenye ze-mold cavity ngesikhathi esisodwa.

Kuphelainhlakai-matrix viscosity inkulu kakhulu, isibopho sinamandla kakhulu, ukuze sigeleze ngezintambo eziqinisayo, ngakho-ke inqubo yokubumba idinga ukucindezela okukhulu kokubumba, okudinga isikhunta sensimbi esinamandla amakhulu, ukunemba okuphezulu nokumelana nokugqwala, futhi kudinga ukusetshenziswa komshini wokunyathelisa oshisayo okhethekile ukulawula izinga lokushisa lokubumba ukuphulukisa, ingcindezi, isikhathi sokubamba kanye neminye imingcele yenqubo.

Indlela yokubumba yokusebenza kahle kokukhiqiza, ukunemba kosayizi womkhiqizo, isiphetho esiphezulu, ikakhulukazi isakhiwo esiyinkimbinkimbi semikhiqizo eyinhlanganisela yezinto ezibonakalayo ngokuvamile ingabunjwa kanye, ngeke ilimaze ukusebenza kwemikhiqizo eyinhlanganisela yezinto. Ukushiyeka kwayo okuyinhloko ukuthi ukuklama kwesikhunta nokukhiqiza kuyinkimbinkimbi kakhulu, ukutshalwa kwezimali kokuqala kukhulu. Nakuba inqubo yokubumba inamaphutha angenhla, inqubo yokubumba isikhunta isabambe isikhundla esibalulekile enqubweni yokubumba impahla eyinhlanganisela.

1, Ukulungiselela

Yenza umsebenzi omuhle weprepreg, ukubumba isikhunta samathuluzi, ngesiqephu sokuhlola isithando somlilo sokusekela, futhi uhlanze isikhunta ekusetshenzisweni kokugcina kwe-resin esele, imfucumfucu, ukugcina isikhunta sihlanzekile futhi sibushelelezi.

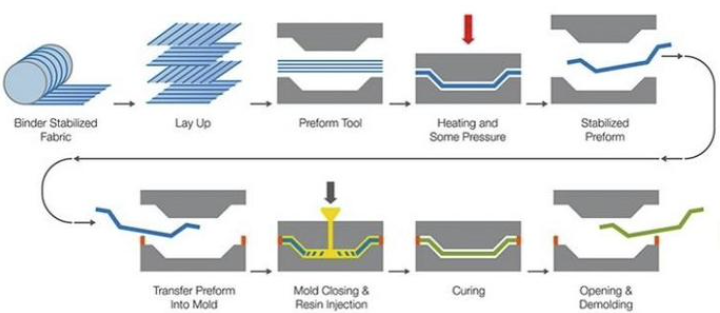

2. Ukusika nokubeka ama-prepregs

Izokwenziwa umkhiqizo we-carbon fiber izinto zokusetshenziswa zokusetshenziswa ezilungile, prepreg ngemuva kokudlulisa isibuyekezo, ubale indawo yezinto ezingavuthiwe, izinto zokwakha, inani lamashidi, ungqimba lwempahla eluhlaza ngongqimba lwempepho engezwe, ngasikhathi sinye ekuphakameni kwento ye-pre-pressure, icindezelwe esimweni sokujwayelekile, ikhwalithi yenombolo ethile yezinhlangano eziminyene.

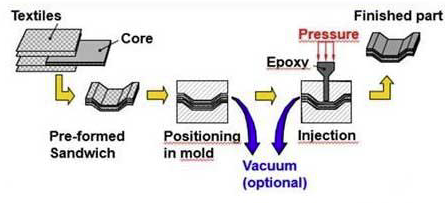

3. Ukubumba nokwelapha

Beka izinto zokusetshenziswa ezinqwabelene esikhunjeni, futhi ngesikhathi esifanayo kuma-airbag epulasitiki angaphakathi, vala isikhunta, yonke into emshinini wokubumba, ama-airbag epulasitiki angaphakathi kanye nokucindezela okuthile okungaguquki, izinga lokushisa elingaguquki, setha isikhathi esingaguquki, ukuze ukuphulukiswa kwayo.

4. Ukupholisa nokudiliza

Ngemva kwenkathi yesikhathi ingcindezi ngaphandle isikhunta kuqala amakhaza ukwazi isikhathi esithile, bese uvula isikhunta, demolding ngaphandle kweso ukuhlanza isikhunta tooling.

5. Ukucubungula ukubunjwa

Ngemva kokudiliza umkhiqizo udinga ukuhlanzwa, ngebhulashi lensimbi noma ibhulashi lethusi ukuze kukhuhlwe ipulasitiki esele, futhi kuphephethwa ngomoya ocindezelweyo, umkhiqizo obunjiwe uyapholishwa, ukuze ubuso bushelelezi futhi buhlanzeke.

6, Ukuhlolwa okungonakali kanye nokuhlolwa kokugcina

Ukuhlolwa okungabhubhisi kanye nokuhlolwa kokugcina kwemikhiqizo kwenziwa ngokuvumelana nezidingo zemibhalo yokuklama.

Ukuhlaziywa kwamaphuzu ezobuchwepheshe wenqubo yokubumba i-prepreg

Kusukela ekuzalweni kwezinhlanganisela ze-carbon fibre, ibilokhu inqunyelwe izindleko zokukhiqiza kanye nomthelela wamabhithi okukhiqiza, futhi ayizange isetshenziswe ngobuningi. Nquma izindleko zokukhiqizwa kwe-carbon fibre futhi ukushaya kuyinqubo yokubumba,i-carbon fiber composite materialinqubo yokubumba kukhona eziningi, ezifana RTM, VARI, hot press amathangi, kuhhavini curing prepreg (OOA), njll, kodwa kukhona amabhodlela amabili: 1, isikhathi umjikelezo wokubumba side; 2, intengo iyabiza (uma iqhathaniswa nezinsimbi namapulasitiki). I-Prepreg CompressionMolding, njengohlobo lwenqubo yokubumba, ingakwazi ukubona ukukhiqizwa kwe-batch futhi inciphise izindleko zokukhiqiza, ezisetshenziswa kakhulu futhi kabanzi.

Prepreg ukubumba inqubo libhekisela izinga lokushisa, ingcindezi, esikhathini esithile kuyoba prepreg ukusabalala singene pre-emise ukubumba umzimba zlib. Ijubane lokubumba lale nqubo liyashesha, izidingo zemishini zilula, kulula ukuyisebenzisa, uma kuqhathaniswa nethangi lokucindezela elishisayo, inqubo ye-VARI ne-OOA, umkhiqizo uhle kakhulu kuzo zombili ikhwalithi ebonakalayo ebusweni, ukuzinza okuhle kwe-dimensional, inqubo kulula ukuyilawula.

▲Ishadi lokugeleza lenqubo yokubumba ngaphambi kokukhulelwe

Izakhi ezine zenqubo yokubumba

1. Izinga lokushisa nokufana: ukukhombisa izinga lokusabela phakathiinhlakafuthii-ejenti yokwelaphakanye nokufana kwesikhundla sokusabela, ngokuyinhloko ukulawula ikhwalithi yendawo yokubumba kanye neziqu zokuphulukisa;

2. Ukucindezela nokufana: ukukhombisa ukukhishwa komoya kanye nomphumela wokugeleza ku-resin, ukulawula ikhwalithi yendawo yokubumba kanye nezakhiwo zemishini;

3. Ubude besikhathi sokwelapha: ukukhombisa izinga lokuphulukisa, ukuqinisekisa ukusebenza kahle kokukhiqiza;

4. Ugqinsi lwesikhunta: ukukhombisa ukujiya komkhiqizo, ngokuya ngezici ezikhethekile ze-carbon fiber material uqobo, klama ukujiya komgodi okunengqondo.

Ukusebenza kwenqubo

Prepreginqubo yokubumba ingakwazi ukukhiqiza noma yisiphi isakhiwo somkhiqizo, isakhiwo somkhiqizo uma siyinkimbinkimbi kakhulu, njengebhande elihlanekezelwe, indawo eningi kakhulu ye-flange, okuholela ekwenyukeni okukhulu kwezindleko zokubunjwa nobunzima bokukhiqiza, ngakho-ke ukwakheka kwezingcezu eziyinkimbinkimbi zokusebenziseka akuqinile, kodwa singaba ukuthuthukiswa kwesakhiwo noma ukuklama kwe-block + izixazululo zokubopha ukuze senze izingxenye eziyinkimbinkimbi.

Ubuchwepheshe obuhlobene

1. Multi-layer Cutting Technology: Multi-layer prepregs asikwa ngesikhathi esisodwa; ama-prepregs anama-engeli ahlukene asikwa ngesikhathi esisodwa ukuze kuthuthukiswe ukusebenza kahle kokusika.

2. Ubuchwepheshe bokushisa-ngaphakathi / obushisayo: isikhunta sishiswa ngokuqondile ekushiseni okuphulukisayo, futhi i-preform ifakwe esikhunjini futhi icindezelwe ibe yisimo, esinciphisa isikhathi sokubumba futhi sinciphise ukusetshenziswa kwamandla.

3. Ubuchwepheshe bokubumba usayizi wenetha: i-preform ishaywa ngosayizi wenetha kuqala, bese ifakwa esikhunjini sosayizi wenetha ukuphulukisa, kunciphisa inqubo yokusika.

Ubunzima Benqubo

Ubunzima bokuklama isikhunta semikhiqizo yesakhiwo esiyinkimbinkimbi: Uma kukhona amabhande amaningi ahlanekezelwe kanye namakhona angalungile emikhiqizweni, kuzokwenza isikhunta sibe nzima kakhulu ukukhiqiza, futhi ngasikhathi sinye, ngemuva kokusetshenziswa kokubunjwa isikhathi eside, kuzoholela ekwehleni kokunemba kokudidiyelwa kwezikhundla zokufakwayo. Ngakho-ke, lapho uklama umkhiqizo, zama ukugwema ibhande elihlanekezelwe noma i-engeli engalungile.

Qaphela: izingxenye zesembozo sangaphandle zezidingo zekhwalithi yomkhiqizo ziphezulu kakhulu, izingxenye ze-carbon fiber zezinkinga ezivamile yilezi: izingxenye zokuthungwa kwamazolo zomkhiqizo amabala amhlophe; izinkinga zokuthungwa okungcolile komkhiqizo; izikhonkwane ezingaphezulu, ukuntuleka kwezinkinga zeglue, njalonjalo. Ukufingqa izizathu, i-ejenti yokwelapha ku-prepreg ayixubene ngokulinganayo noma ukusabela akuphelele; izinga lokushisa lesikhunta alifani; izinga lokushisa nokucindezela akukho endaweni; ukwakheka kanye nokucubungula isikhunta akukho endaweni; inqubo yokubumba ayilawulwa; isikhuntai-ejenti yokukhululaiyasabela, njalo njalo.

Isikhathi sokuthumela: Jan-17-2025