November 4, 2024– Syensqo, a global leader in advanced materials, and Bell Textron Inc., a subsidiary of Textron Inc., have entered into a strategic collaboration aimed at accelerating the industrialization of composite manufacturing for next-generation aerospace applications. The partnership will leverage Syensqo’s innovative Direct Dry Fiber (DDF) placement technology and the CYCOM® EP2750 fast-curing prepreg system to enhance production efficiency and reduce costs for complex aerostructures.

1. Technological Breakthrough: From Hours to Minutes in Cure Time

Traditional autoclave-based curing processes for aerospace-grade carbon fiber composites are time-consuming and energy-intensive, limiting large-scale adoption. Syensqo’s CYCOM® EP2750 epoxy prepreg system addresses this challenge by achieving full cure within minutes—over 70% faster than conventional materials—while requiring only an oven rather than an autoclave. The material maintains T800-grade mechanical properties, making it suitable for primary structures such as those used in Bell’s V-280 Valor tiltrotor aircraft.Its compatibility with curved and intricate geometries ensures uniform fiber placement and resin infusion, enabling the mass production of large components without compromising performance.

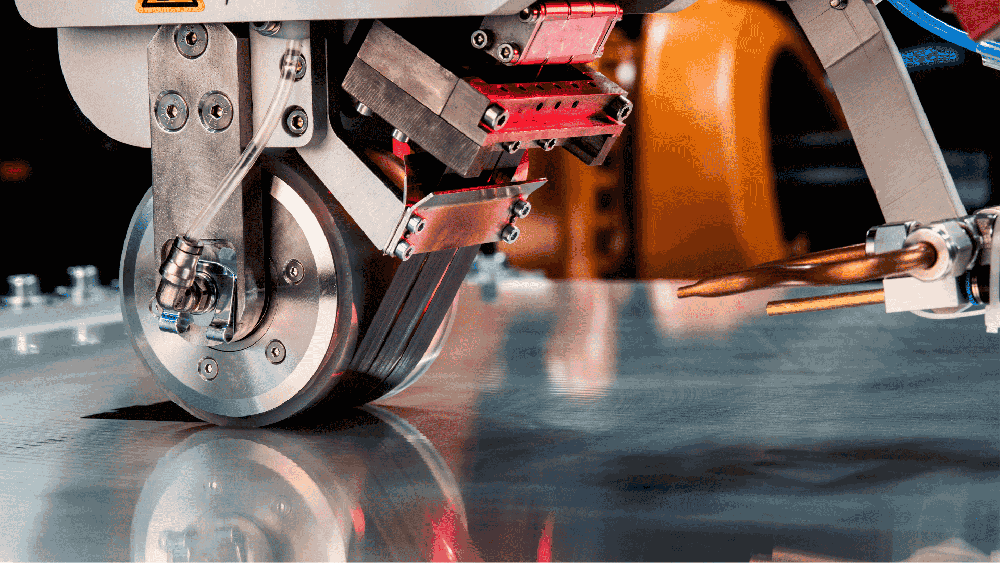

2. Integrated Process: DDF + Fast-Curing Prepreg

Syensqo’s DDF technology enables precise dry fiber placement with controlled orientation and resin content, seamlessly integrating with the CYCOM® EP2750 system. This “dry-wet” synergy allows real-time adjustments during layup, optimizing performance for wings, fuselages, and other complex shapes.Bell plans to apply this integrated approach to components such as rotor cowlings and nacelles for the Bell 429 helicopter, targeting a 40% reduction in production cycle time and lower factory footprint and labor dependency.

3. Industry Context: Shift from Material Innovation to Manufacturing Efficiency

The Syensqo-Bell collaboration reflects a broader industry trend where material suppliers and OEMs jointly develop tailored manufacturing solutions. While other players—such as Covestro with GKN Aerospace (UV-curing composites) and Arkema with Airbus (thermoplastics)—focus on alternative pathways, Syensqo’s strategy emphasizes a scalable, oven-only process that aligns with existing aerospace supply chains without requiring heavy capital investment.

4. Implications for Chinese Composite Manufacturers

Although China has achieved breakthroughs in T700/T800 carbon fiber production, reliance on imported prepregs and foreign process specifications remains a bottleneck. The Syensqo-Bell model offers key insights:

∙Strengthen material-process co-developmentto build integrated capabilities;

∙Prioritize low-cost, high-speed techniques like fast compression molding or resin infusion for mass production of secondary structures;

∙Collaborate with eVTOL and UAV manufacturers to pilot agile manufacturing chains and drive iterative technology adoption.

Conclusion

The partnership between Syensqo and Bell signals a pivotal shift from lab-scale customization to factory-ready scalable production in aerospace composites. For China to compete globally, closing the gap in manufacturing technology—not just materials—will be critical in the coming decade.

Post time: Nov-05-2025