R&D of Kingoda Fiberglass

Kingoda Fiberglass Manufacturing Co., Ltd. as a technology-based enterprise, has a deep understanding of "science and technology is the first productive force" and always puts "revitalizing the enterprise through science and technology" in the first place. The surface treatment technology successfully developed by our factory in 2003 promoted the rapid development of our fiberglass manufacturing; In 2015, we raised funds to start the construction of the R & D center. By the end of 2016, it was equipped with advanced sample preparation, analysis and testing equipment, which provided great convenience for the development of fiberglass and composite products. It has become an advanced and perfect product development and Application Center in the industry and was rated as a municipal enterprise technology center in 2016.

The company have been engaged in basic research and new technology research and development of fiberglass and its composites with many for a long time. It has successively presided over and undertaken a number of national, provincial and horizontal scientific research projects in the field of fiberglass and its composites, including the theory and method of characterization of fiberglass micro structure, the interface between fiberglass and resin, the mechanism of fiberglass reinforcement, the preparation and forming technology of fiberglass reinforced composites We have carried out in-depth and detailed work on the new connection technology of fiberglass reinforced thermoplastic composites, accumulated rich research results, and formed a stable research direction and research team.

Research and Testing Equipment

● Research and development of glass formula and precursor forming process: it has computer workstation and large-scale numerical simulation software, special glass melting equipment, single wire drawing furnace for research and development, etc.

● In aspect of analytical and testing instruments: it has an X-fluorescence analyzer (Philips) for rapid analysis of mineral raw materials, an ICP trace element detector (USA), a particle size analyzer for mineral raw materials, a glass oxidation atmosphere tester, etc.

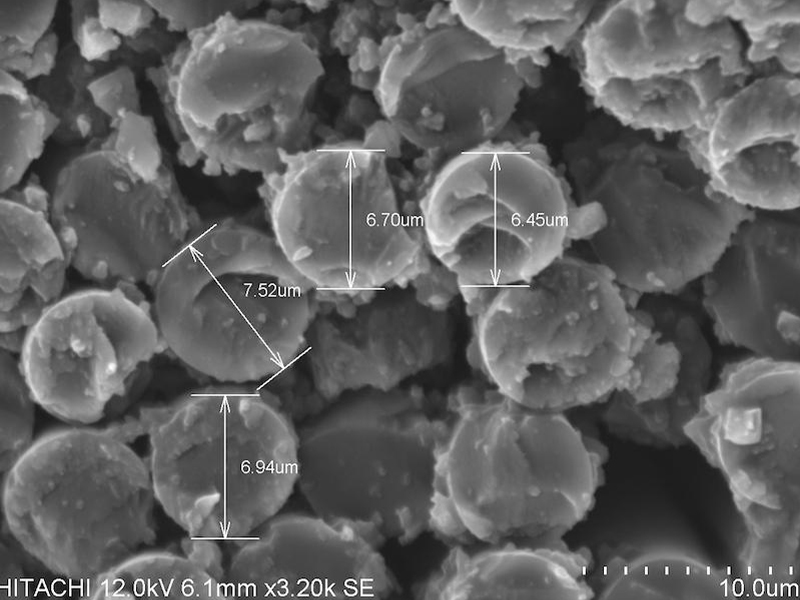

Scanning Electron Microscope

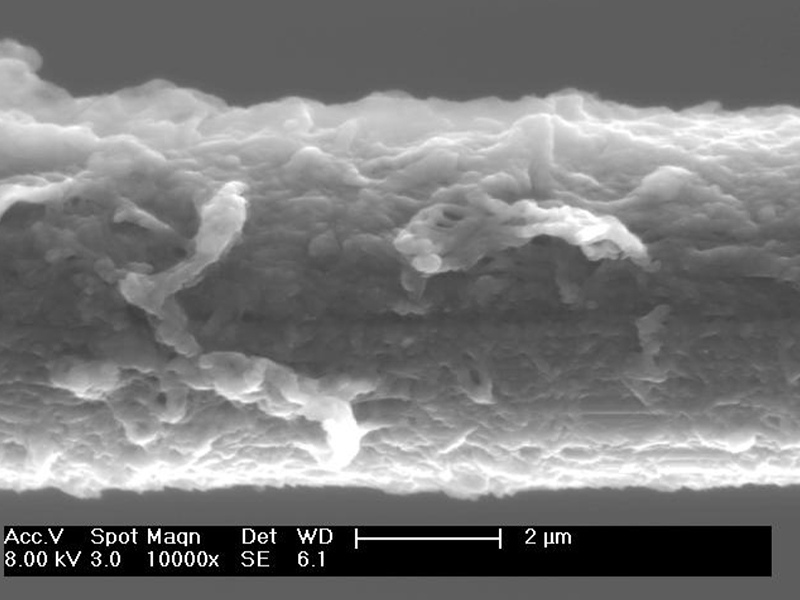

SEM Inspection On Fiber Surface

SEM Inspection On Fiber Surface

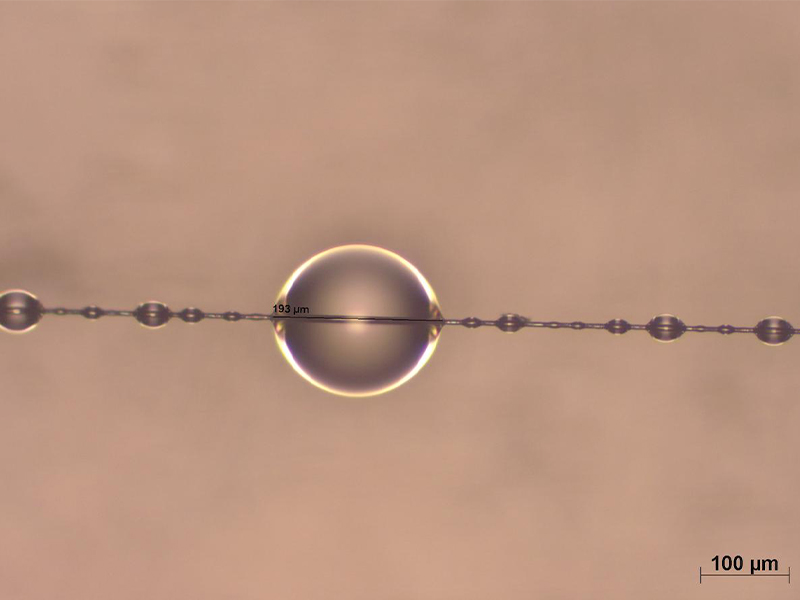

Interface Analysis with Optical Microscope

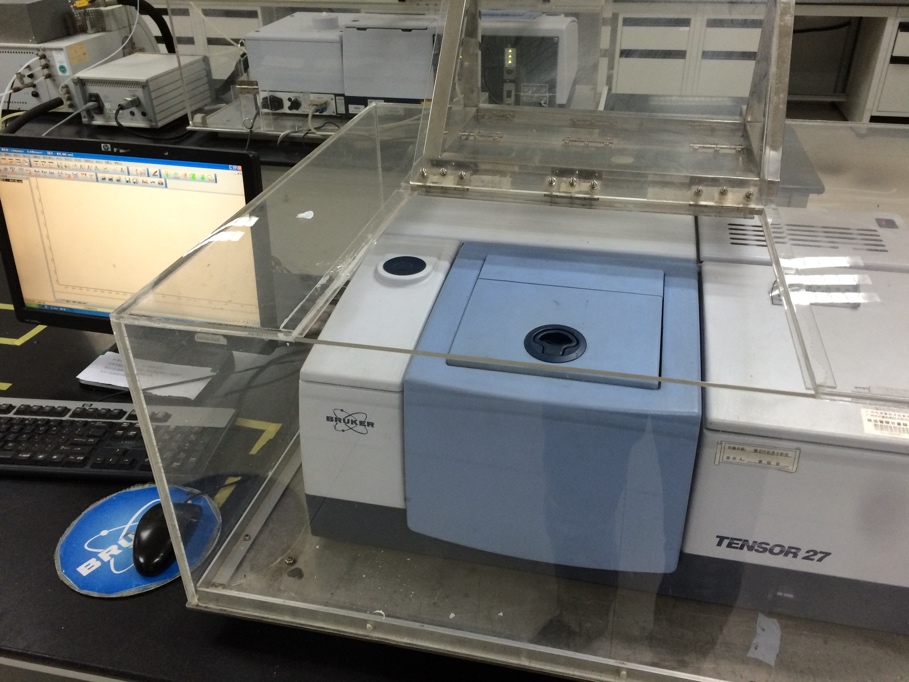

Fourier Infrared Spectrum Analyzer:

Development of film-forming agents and additives for fiberglass surface treatment: it has high-pressure reactor, gas chromatography analyzer, spectrophotometer, chroma detection analyzer, flame photometer, electrostatic instrument, high-speed centrifugal analyzer, rapid titrator and surface tension instrument for measuring interface contact angle, and particle size detector of wetting agent raw materials imported from Britain, Thermogravimetric analyzer imported from Germany.

Vaccum Bagging Infusion:

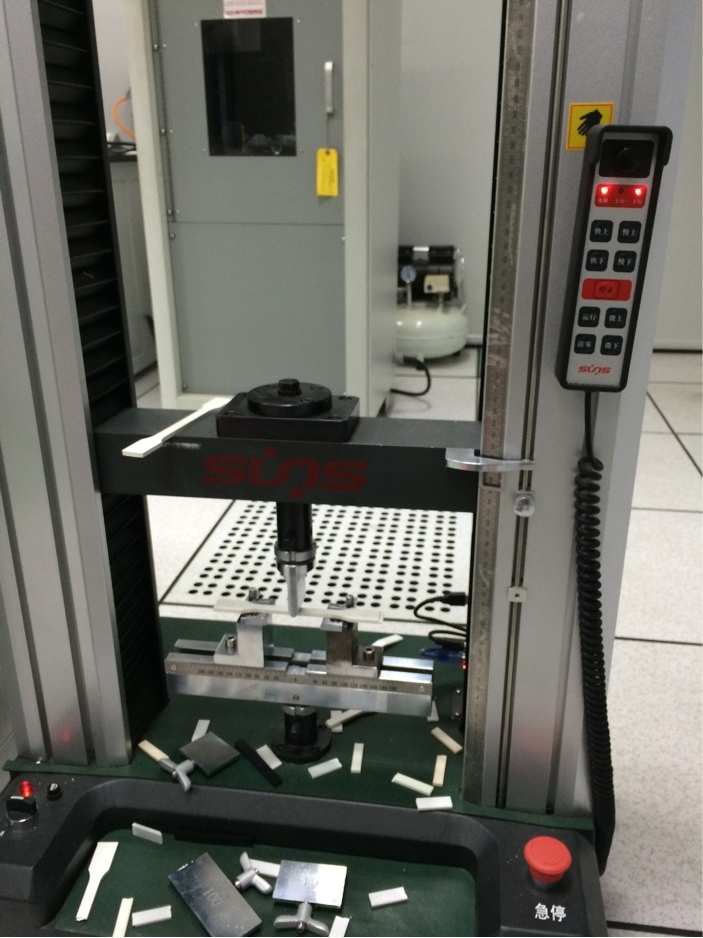

Lab scale production for fiberglass and composite materials: there are winding unit, pultrusion unit, SMC sheet unit, SMC molding machine, twin-screw extrusion unit, injection molding machine, BMC unit, BMC molding machine, universal testing machine, impact instrument, melting index instrument, autoclave, hairiness detector, flight detector, chromaticity detector, electronic cloth loom and other instruments and equipment.

Mechanical Testing for Tensile and Bending:

In aspect of microscopic analysis and detection of fiberglass and composites: it has 4 electron microscopes such as Philips transmission electron microscope and Fei thermal field emission scanning electron microscope, and is equipped with electron backscatter diffraction system and energy spectrometer; Three X-ray diffractometers of different specifications and models are used for structural analysis, including one latest Japanese science D/max 2500 PC X-ray diffractometer; It has several sets of various types of chemical analysis equipment, including liquid chromatograph, ion chromatograph, gas chromatograph, Fourier transform infrared spectrometer, laser Raman spectrometer and chromatography-mass spectrometry.

In aspect of fiberglass manufacturing, Kingoda Fiberglass Manufacturing Co.,Ltd. has mastered the key technologies of fiberglass production, and has strong research, development and industrialization ability In aspect of new products, new processes and new technologies, especially in key technologies such as platinum leak plate processing, wetting agent and surface treatment. The 3500 ton production line designed by the company was put into operation in 1999, with a running time of 9 years, becoming one of the production lines with the longest service life in the fiberglass industry; The 40000 ton E-CR production line designed by the company was put into operation in 2016; The design and processing level of platinum leakage plate has also been significantly improved. The design and processing level of small aperture porous number spinning leakage plate ranks first in China, and a leakage plate that can produce super spinning has been developed. In aspect of surface treatment technology, Kingoda Fiberglass Manufacturing Co.,Ltd. is the first manufacturer to make a breakthrough. The successful implementation of the project has promoted the rapid development of the enterprise and the rapid development of domestic fiberglass. At present, the production capacity of special surface treatment agent reaches 3000 tons/year. The developed thermoplastic chopped fiber has reached the international advanced level, and many world-class industry leading companies became our customer. At present, the company has 25 R & D person, including 3 doctors and more than 40% of middle and senior technicians. The key links of fiberglass development and production have strong R & D ability and perfect fiberglass R & D conditions.

The fiberglass roving products of Kingoda Fiberglass Manufacturing Co.,Ltd. won the title of China's famous brand product in 2019, and E-CR fiberglass was rated as a national key new product in 2018.

Our company owns more than 14 related invention patents and published more than 10 relevant academic papers.