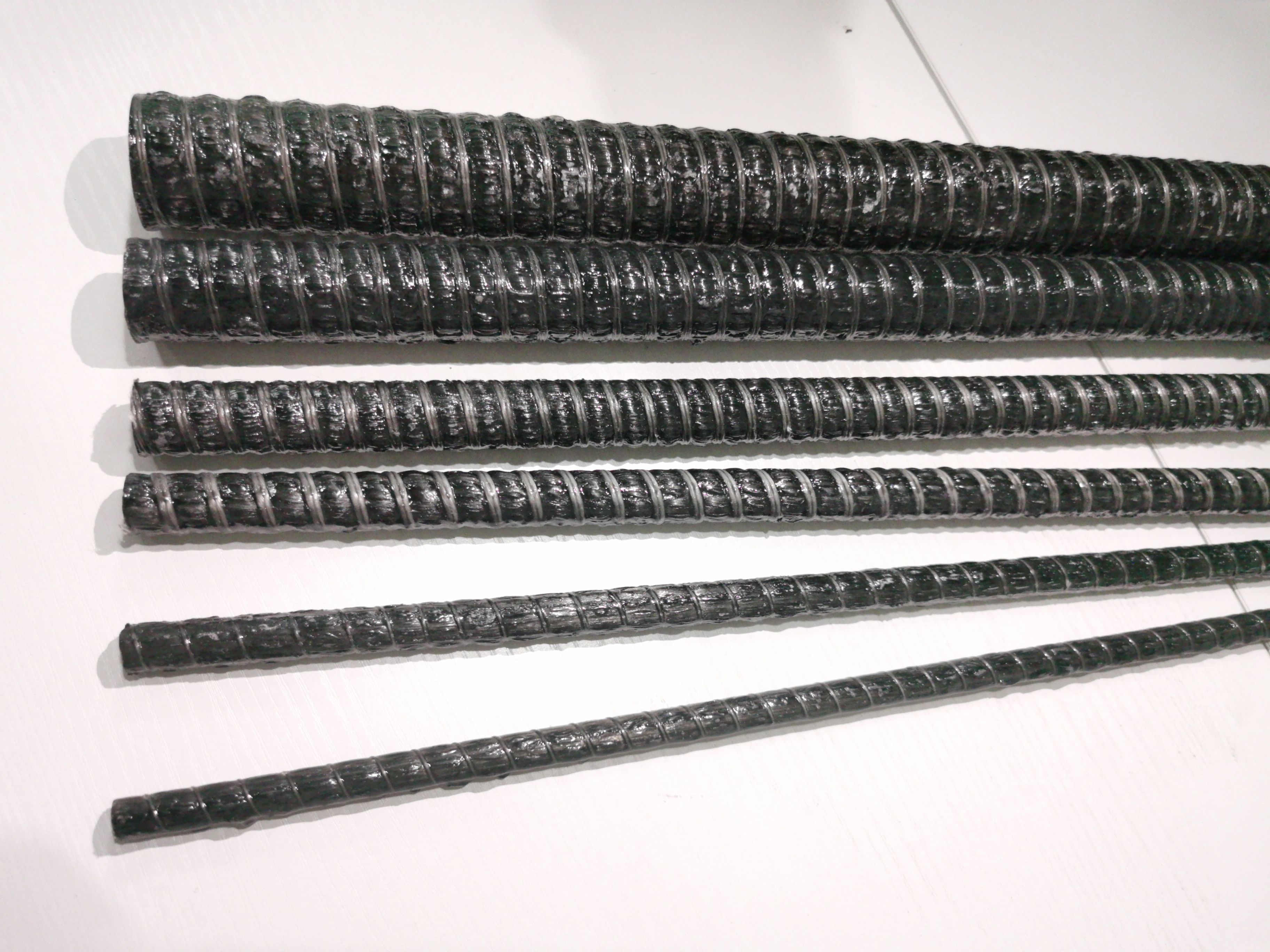

High Performance Fiberglass Reinforce Epoxy Rebar

Fiberglass Reinforce Epoxy Rebar Has:

- Lightweight yet strong: Fiberglass composites are known for their excellent strength-to-weight ratio. It provides the necessary structural integrity while keeping the overall weight of the product low.

- Durability and Resilience: Our fiberglass composites are highly durable and resilient, making them suitable for applications subject to heavy loads, vibration and shock. It has excellent resistance to external factors such as moisture, chemicals and UV radiation.

- Design flexibility: The unique properties of fiberglass composites allow for complex and custom designs. It can be easily molded or formed into complex shapes, enabling manufacturers to create innovative and visually appealing products.

- Cost-effective solution: By using fiberglass composites, manufacturers can save costs without compromising the performance and quality of the final product. Its long service life and corrosion resistance also help reduce maintenance and replacement costs.